news center

What are insulated bearings ?

2024-10-31

Insulated bearings are specially designed to prevent electrical current from passing through the bearing. They are used in applications where electrical arcing could damage the bearing or the surrounding components, such as electric motors, generators, and turbines.

Insulated bearing types mainly include the following:

Ceramic insulated bearings: ceramic materials are used to manufacture rolling bodies or inner and outer rings, which have good insulating properties and high temperature resistance. Ceramic materials can isolate the current and prevent galvanic corrosion.

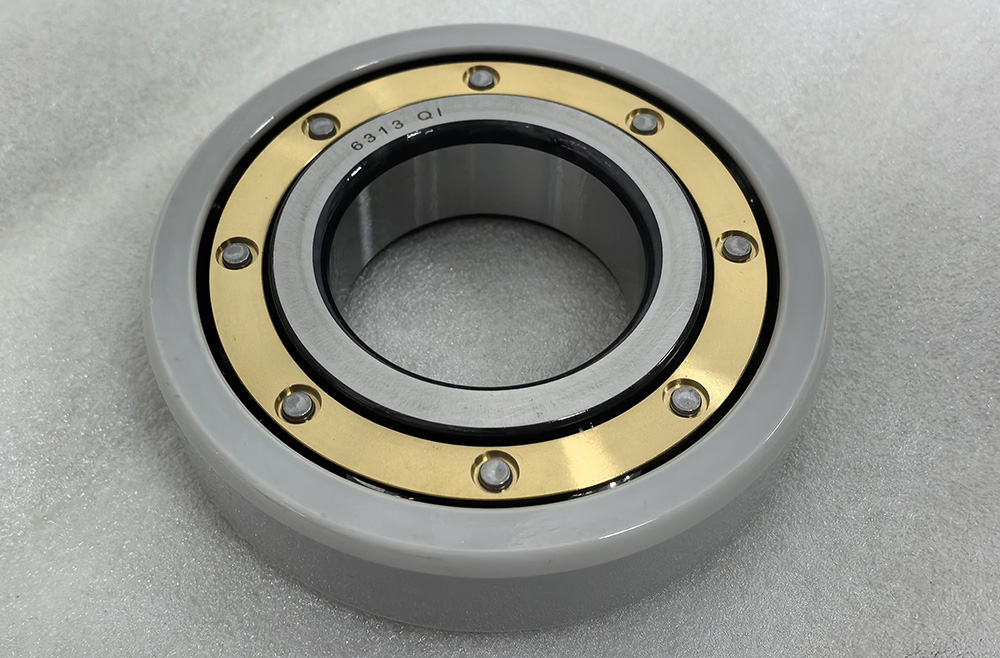

Coated insulated bearings: By applying an insulating coating to the outer or inner ring of the bearing, the current is prevented from passing through the bearing, effectively preventing galvanic corrosion. This type of bearing is commonly used in electrical equipment such as motors.

Hybrid Insulated Bearings: Hybrid insulated bearings are those in which the rolling body is made of ceramic material while the inner and outer rings are made of steel. This design not only provides an insulating effect, but also retains the mechanical properties of steel.

Electrically Insulated Bearings (INSOCOAT): The outer or inner ring of the bearing is coated with aluminum oxide, which has excellent insulating properties, and is used in high-voltage electrical equipment to protect the bearings from damage caused by electrical currents.

These bearings are widely used in electric motors, generators, wind turbines and power transmission equipment to effectively prevent current from passing through the bearings, avoiding galvanic damage and extending equipment life.

The main categories of electrically insulated bearing products are: electrically insulated deep groove ball bearings, electrically insulated angular contact ball bearings, electrically insulated cylindrical roller bearings and so on.

Advantages of electrically insulated bearings

Avoid damage caused by electrical corrosion, so compared with ordinary bearings, they can be used in motors to ensure more reliable operation. Compared with other insulation methods, such as shaft or housing insulation, they are more cost-effective and reliable. They are suitable for motors, generators, and especially variable frequency motors.

If you have any questions about electrically insulated bearings, welcome to contact us!